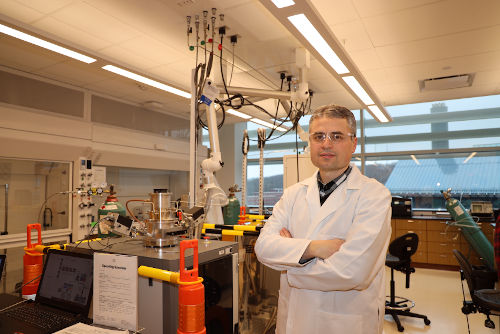

Faculty Spotlight: Dr. Necmi Biyikli’s Atomic Layer Engineering Laboratory: Building the Next Generation Devices, one Atomic Layer at a Time…

By Sowon Chung

Dr. Necmi Biyikli is an Electrical and Computer Engineering Assistant Professor at the University of Connecticut. Before joining UConn in 2017, he was an Assistant Professor at Bilkent University, Turkey. His areas of expertise focus on atomic layer deposition (ALD), semiconductor thin films, (opto) electronic devices, nanoscale energy materials, flexible and wearable electronics, smart/tunable materials, environmental sensing, and selective materials processing.

Dr. Biyikli’s Ph.D. was on semi-conductor materials and devices. He specifically focused on the widegap III-nitride family, which have revolutionized the lighting technology with blue LEDs and high-frequency power chips for 5G communication systems. His postdoctoral research encompassed the epitaxial growth of nitride semiconductor materials at high temperatures, typically above 1000 °C.

In his own independent research lab, Dr. Biyikli focused on the low-temperature synthesis of the III-nitride compounds using the emerging atomic layer deposition (ALD) technique. Besides dramatically lower growth temperatures, ALD provides thickness control at the atomic scale and features near-ideal uniformity even on very high-surface area highly complex 3-D nanostructures. Dr. Biyikli’s Atomic Layer Engineering (ALEng) Lab is one of the leading plasma-ALD research groups worldwide particularly in III-nitride ALD research. If the ultimate goal of device-quality film synthesis can be achieved at low temperatures via ALD, this might trigger a huge impact in future device technologies.

Another area of research Dr. Biyikli focuses on is the synthesis of oxide and metal films. This research is very applicable in real life. Metal and oxide films are very important in microelectronic chip manufacturing. Transistors are being manufactured with amazingly smaller features – nowadays reaching below 5 nm critical feature size – which requires each film to be atomically precise. Consequently, ALD has become increasingly critical for such demanding device structures to be fabricated in high volumes. Companies like Intel and Samsung are therefore investing heavily in ALD technology. ALD has also started to find attraction from other industries, particularly in energy conversion and storage. Functional nanometer-sized precision ALD coatings provide very significant performance enhancement in Li-ion, Li-air, and solid state batteries, as well as the rising star of solar cell technology: perovskite solar cells. “ALD is already very well part of our lives as all handheld devices feature billions of transistors which depend on this precision coating technology. Moreover, we most probably will see EV batteries in our cars and roof-top solar cells in our houses with many ALD layers in the next 5-10 years. Our goal is to provide leading-edge research output to both basic and applied aspects of this atomic precision manufacturing technology of the future” says Dr. Biyikli.

Dr. Biyikli enjoys investigating processes that have not yet been explored or understood. He is one of the scholars at the forefront of this specific atomic-scale materials research field. He also likes to conduct active experiments with his students rather than staying in his office. He appreciates being in the lab, especially in the Engineering Science Building. Its open lab environment provides a nice opportunity to interact with other groups. He enjoys sharing his expertise with the students, meeting with other research group members and developing research collaborations with mutual benefit.